Recyclable up to 100 %.

POLYMELT PP-R & PP-RCT pipes –

sustainability made in Germany.

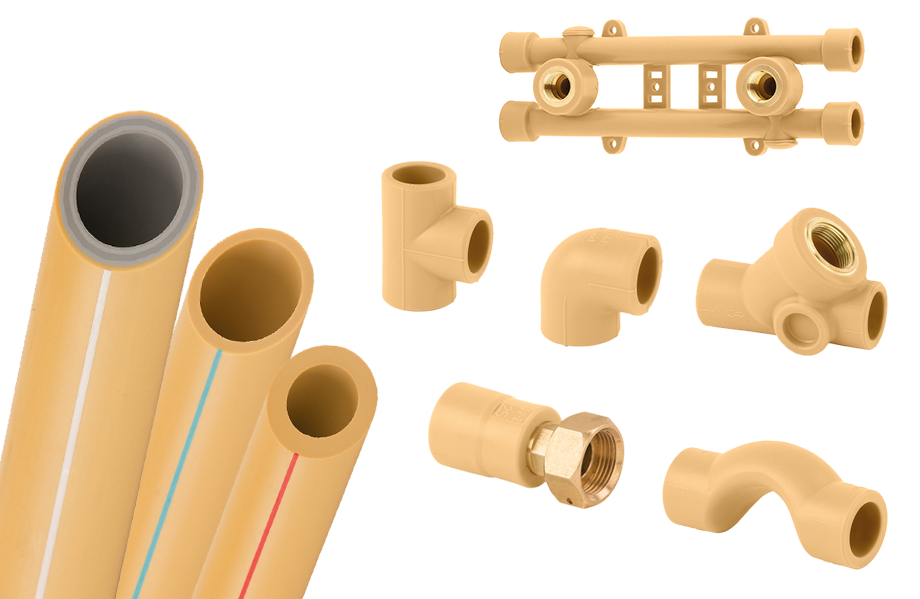

Here at POLYMELT, we recognize the urgent need for sustainable solutions in today’s world. That’s why we’re proud to offer a comprehensive range of high-quality PP-R (Polypropylene Random Copolymer) and PP-RCT (Polypropylene Random Copolymer with Modified Crystallinity and Temperature Resistance) pipes and fittings. These products not only meet the exacting standards of modern construction but also prioritize environmental responsibility:

Shaping the future: Sustainable circular economy at POLYMELT

Our PP-R and PP-RCT plastic pipe systems not only meet the highest quality standards, but also make a sustainable contribution to the circular economy. Where possible, our pipe systems are made from recycled polypropylene, which not only reduces the environmental impact but also contributes to a closed-loop economy.

Using recycled material in our products means that we conserve resources and minimise waste while maintaining the outstanding performance and longevity of our pipe systems. With our commitment to sustainability and innovation, we are helping to create a world where quality and environmental protection go hand in hand.

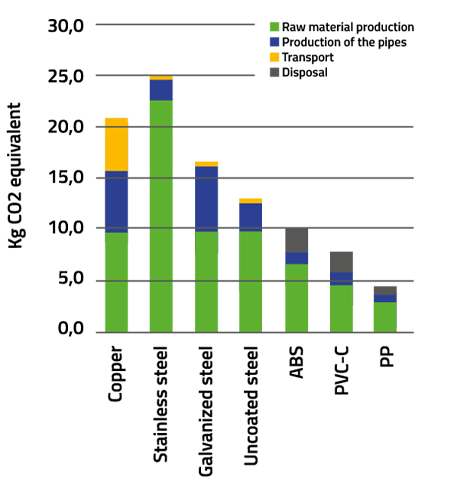

The life cycle assessment of polypropylene plastic pipes is up to 5 times better in terms of CO2 emissions than other pipe systems

What characterises the sustainability of POLYMELT PP-R and PP-RCT plastic pipe systems?

- Longevity: Engineered to endure the lifespan of a building or longer, our PP-R and PP-RCT products reduce the frequency of replacements, thus minimizing waste and promoting sustainability.

- Chemical Safety: With a commitment to purity, our pipes and fittings do not leach harmful chemicals, ensuring the integrity of the water supply and environmental health.

- Energy Efficiency: By maintaining smooth interior surfaces that resist corrosion and scaling, our products minimize pumping energy requirements over time, fostering energy conservation and reducing carbon emissions.

- Leak-Resistance: Our heat-fused connections provide unparalleled leak resistance, mitigating the risk of mold growth and enhancing indoor air quality.

- Toxic-Free: Free of toxic materials and heavy metals, our PP-R and PP-RCT solutions uphold the highest standards of safety and environmental integrity.

- Emission-Free Installation: Utilizing heat fusion technology, our products offer flame- and emission-free installation, minimizing environmental impact during construction.

- Contribution to Green Building: Our systems meet the criteria for green building credits, supporting sustainable construction practices and environmentally conscious projects.

- Recyclability: Throughout their life cycle, our PP-R and PP-RCT plastic pipes and fittings are fully recyclable, further reducing environmental footprint and promoting circular economy principles.

- Insulation and Noise Reduction: With inherent insulation properties, our pipes help maintain water temperature and reduce noise transmission, enhancing comfort and efficiency.

- Engineered Durability: Enhanced with heat stabilizers, our PP-R and PP-RCT products withstand temperature fluctuations and maintain long-term performance, even in challenging conditions.

- Versatility: Suitable for direct-buried and trenchless applications, our solutions offer versatility and reliability in various installation scenarios.

- Chemical Resistance: Chemically inert and resistant to corrosion, scaling, and erosion, our products ensure durability and longevity in diverse water environments.

At POLYMELT, sustainability isn’t just a goal – it’s our guiding principle. Join us in shaping a greener, more sustainable future with our PP-R and PP-RCT pipes and fittings.

Sustainable PP-R & PP-RCT piping systems from POLYMELT

ECOSAN

POLYMUTAN

UV

MECHANICAL

KAL-NG

FAQs: Frequently asked questions about the sustainability of PP-R pipes

Are PP-R pipes really more environmentally friendly than other materials?

Yes, definitely. PP-R pipes are free from harmful substances such as lead or other heavy metals. Their production process is energy efficient and the pipes are 100% recyclable. This makes them an environmentally friendly choice compared to conventional materials.

How do PP-R pipes help to conserve resources?

PP-R plastic pipes are characterized by their longevity, which means that they need to be replaced less frequently. This reduces the need for new pipes and thus minimizes the consumption of resources. The pipes are also recyclable, which contributes to a further reduction in the ecological footprint.

Doesn’t the higher temperature resistance affect the environmental footprint?

Although PP-R pipes have improved temperature resistance, this is not at the expense of their environmental footprint. Due to their energy efficiency during production and the reduction in the need for spare parts, the positive impact on the environment outweighs any potential negative effects.

How do PP-R pipes support sustainability initiatives in different industries?

PP-R pipes are used in a variety of sectors, from drinking water supply to industry. Due to their durability, efficiency, and environmental friendliness, they help to support the sustainability goals of various industries.

Does the production of PP-R pipes not cause significant emissions?

The production of PP-R pipes at POLYMELT is designed to minimize energy consumption and reduce emissions. By using state-of-the-art production methods and focusing on energy efficiency, we strive for sustainable production that has minimal impact on the environment.

What effect do PP-R plastic pipes have on energy efficiency?

PP-R pipes, thanks to their smooth inner surface and low friction losses, help to improve energy efficiency. The efficient flow minimizes the need for pumping energy and thus supports the sustainable use of resources.

What role do PP-R pipes play in the circular economy?

PP-R pipes are 100% recyclable and can be returned to the cycle. This supports the idea of the circular economy promoting the reuse of materials while reducing the need for virgin resources.